We have been implementing robotic machines for over three decades and have a large base of installed machines in production. Along the way, we have learned how to put robots to work through sound integration with other automation, clean end of arm tooling, cycle time optimization and quality programming. Our experienced programmers are fluent with multiple robot brands, styles and applications. They can help you optimize cycle time, improve reliability and help you run more quality products.

We have talented mechanical designers who can develop tooling and hardware solutions that will accurately and efficiently update your existing machine to better handle your products and components. Our team can quickly reproduce existing tooling or make enhancements that will help you improve your process and make your applications more robust and add new products.

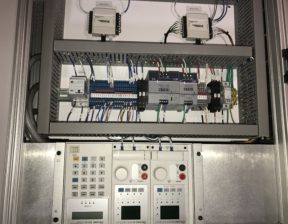

Our well trained and experience staff armed with a laptop and numerous software and applications can efficiently help you navigate your way through machine problems, technology updates and the addition of new products to your automation systems. Our engineers will provide you with well documented, understandable ladder logic and code that will help increase the robustness of your manufacturing systems.

“FAI’s support for us, has been in a word – Outstanding.”

– Manufacturing Engineer, Electronics Manufacturer

HMI

HMIOur staff has experience with large and small scale interface applications. This experience ranges from simple component type HMIs to large scale PC based interfaces and everything in between. Our team can (1) make updates to your existing screens, (2) add new screens or alarms to your existing terminals or (3) replace existing pushbutton stations with new HMI terminals. We maintain our own suites of software for the latest technology in terminals. We also make screen updates to help make things more informative for your operators as well as provide throughput, quality and maintenance data to other users.

We help you enhance your manufacturing process by applying machine vision. Our engineers can tailor a solution to solve your existing problems or provide robustness to your process with additional checks.

We evaluate your needs and scale an application that includes every aspect of a vision installation. Our team will evaluate lighting, lenses, camera type, processors, controller interfaces, software tools, fixtures and mounting methods.